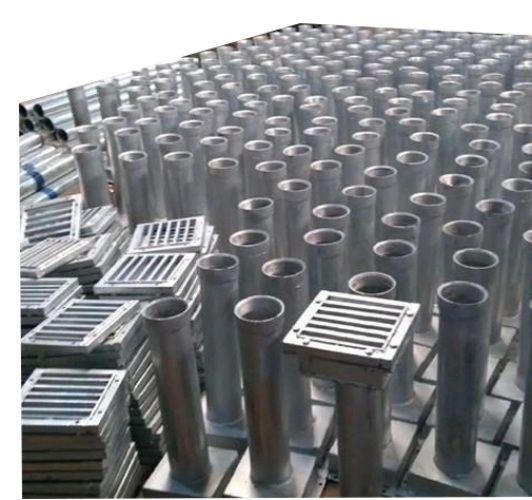

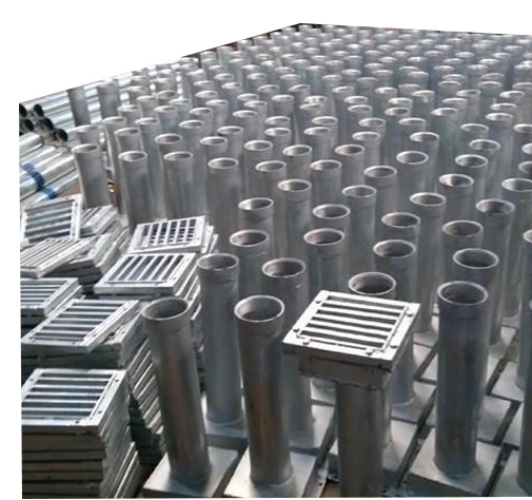

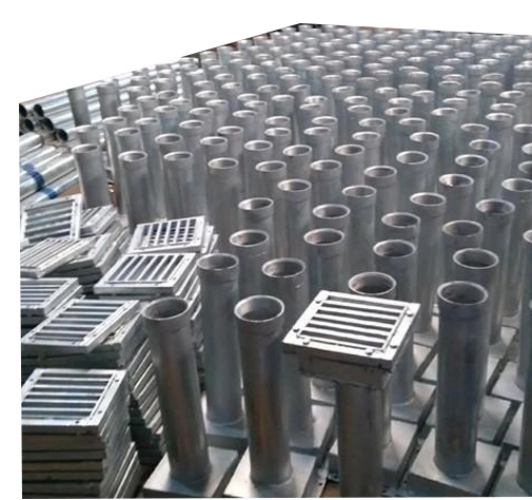

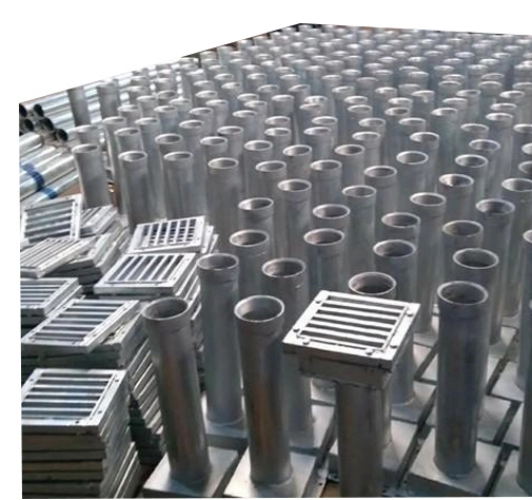

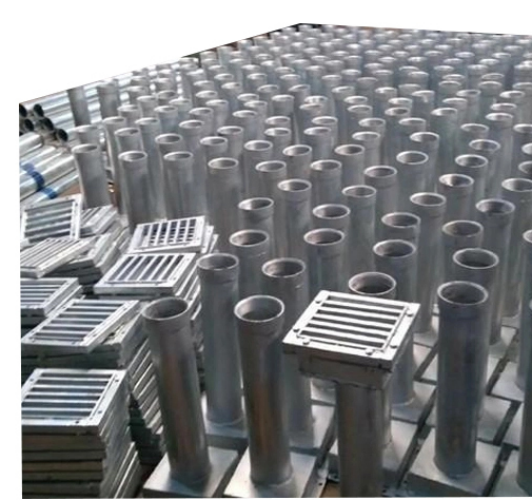

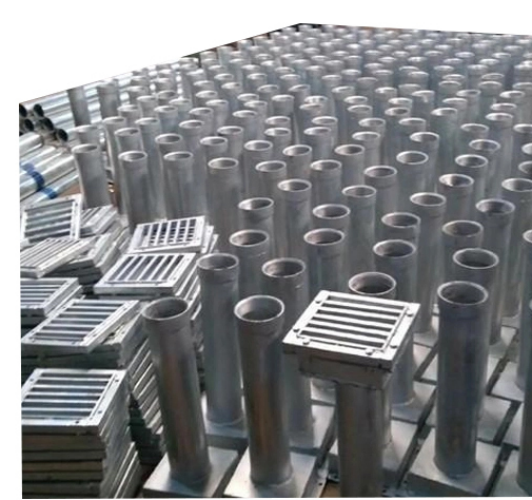

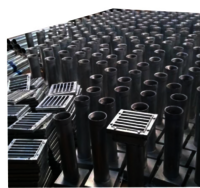

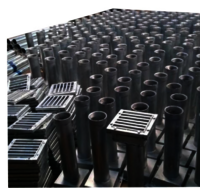

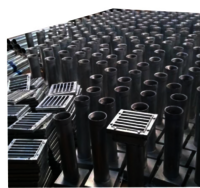

Drainage Spout

Product Details:

- Application Bridge

- Product Type Bridge Drainage Spout

- Main Material Mild Steel

- Surface Treatment Galvanized

- Size Thickness - 6-100 Mm

- Usage Construction

- Feature High Quality

- Click to View more

Drainage Spout Price And Quantity

- 1000 INR/Piece

- 5000 Piece

Drainage Spout Product Specifications

- Mild Steel

- Construction

- Bridge

- Thickness - 6-100 Mm

- Bridge Drainage Spout

- High Quality

- Galvanized

Drainage Spout Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 300000 Piece Per Month

- 10 Days

- All India

Product Description

A Drainage Spout is a structural component installed in bridges, flyovers, and other elevated structures to collect and discharge surface water from the bridge deck. It forms a vital part of the bridge deck drainage system, ensuring that rainwater and surface runoff are efficiently removed to prevent water accumulation and deterioration of the structural elements.

The drainage spout is typically a fabricated or cast outlet unit made from mild steel, galvanized steel, stainless steel, or cast iron, depending on the projects environmental conditions and design requirements. It is positioned at designated deck drain points or scupper locations and conveys collected water through the deck slab to a discharge point below the bridge deck.

The design of the drainage spout ensures watertight performance, corrosion resistance, and long term durability under varying weather and loading conditions. It also allows easy access for maintenance to prevent clogging and ensure the proper functioning of the drainage system throughout the service life of the structure.

Main Features

-

Efficient removal of surface runoff from the bridge deck.

-

Prevents water stagnation and associated damage to deck surfacing and structure.

-

Protects girders, bearings, and substructure from water infiltration and corrosion.

-

Fabricated for durability, watertightness, and ease of maintenance.

-

Corrosion resistant through galvanizing or epoxy coating.

-

Can be adapted for different deck types and slopes.

Typical Components

-

Spout Body / Pipe:

A circular or rectangular pipe that carries the water from the deck surface to the underside of the bridge. -

Flange or Collar:

A flat steel plate or cast ring welded around the spout to ensure a watertight joint with the deck concrete. -

Grating / Inlet Cover:

A cast iron or steel grating provided at the inlet to prevent entry of debris while allowing free flow of water. -

Downpipe / Chute Connection:

Attached below the spout to safely discharge water away from structural elements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS