Our Products

MOST POPULAR PRODUCTS

we are working with the mission of become a market leader in infrastructure development

1. Scope

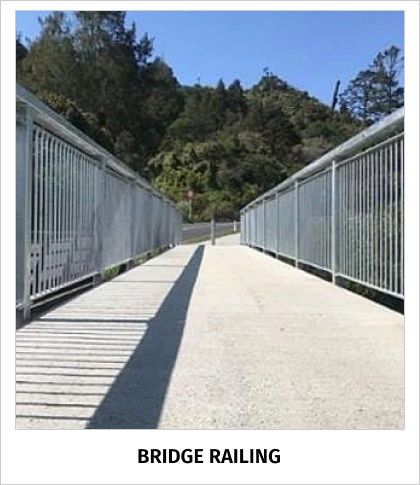

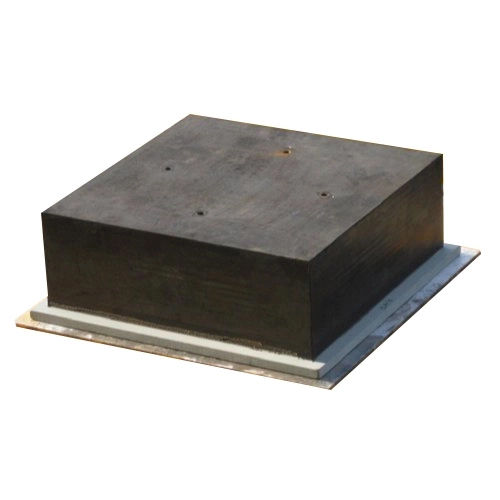

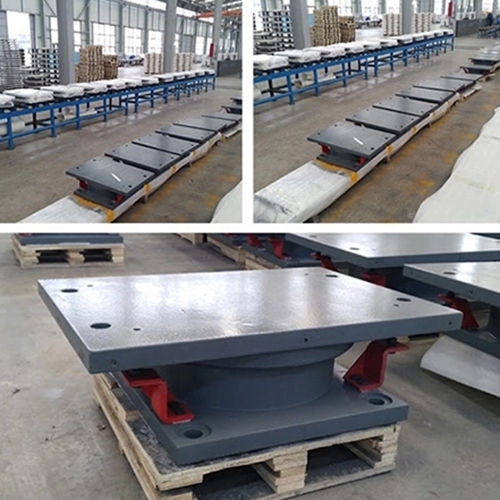

This specification covers the design, materials, manufacture, testing, supply, and installation of Rocker Cum Roller Bearings for bridge structures.

These bearings shall be designed to transmit loads safely from the superstructure to the substructure while allowing the necessary rotations and longitudinal movements of the bridge deck due to temperature variation, creep, shrinkage, and live load effects.

2. General Description

A Rocker Cum Roller Bearing combines the features of a rocker bearing and a roller bearing.

It consists of a roller assembly that allows longitudinal movement and a rocker plate or pin that accommodates rotational movement.

This dual action permits the bearing to:

Transfer vertical loads effectively,

Allow controlled longitudinal displacement, and

Permit angular rotation of the superstructure.

The assembly ensures smooth operation, durability, and minimal maintenance during the service life of the bridge.

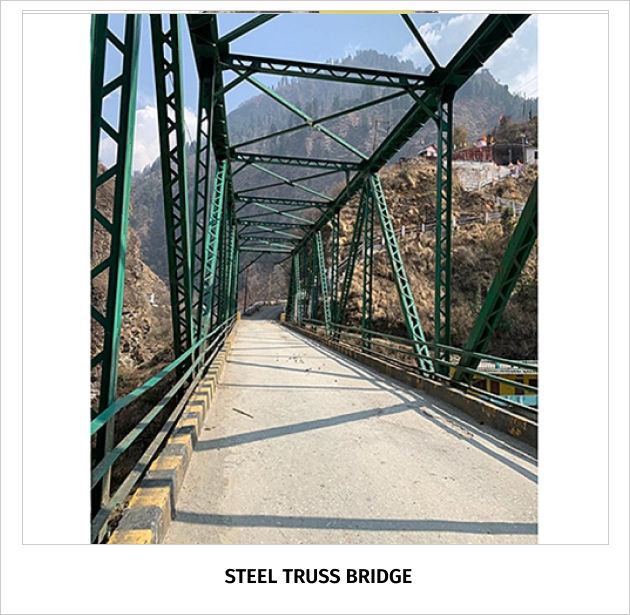

Steel truss bridge specifications cover geometry (span, width, truss type like Warren/Pratt), loads (dead, live, wind, snow), materials (corrosion-resistant steel), design codes (AASHTO/AISC), detailing (connections, members), and quality control (traceability, coatings) for safe, economical spans, typically 100-200+ feet, balancing strength with site needs. Key elements include member sizing for tension/compression, deck design for traffic, and load factor application, ensuring performance over varying spans.

Key Specification Areas

Geometric & Configuration:

Span: Common range 75-250+ feet; defined by bearing centerline.

Width: Varies with traffic (e.g., 2-lane, 3-lane).

Truss Type: Warren (common, simple), Pratt, Howe, K-truss.

Skew: Can be arranged to match site geometry.

About Us

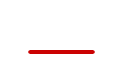

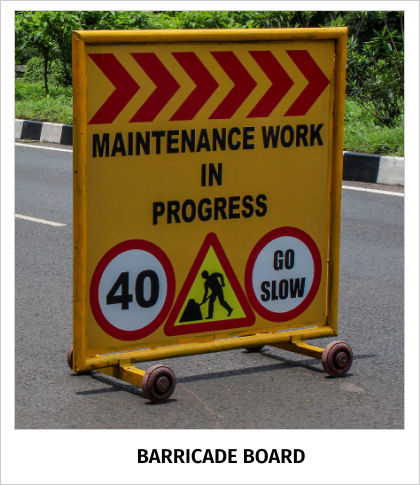

Serving customers with products such as Bridge Railing, Barricade Board, Diversion Board, Mild Steel Bridge Floor Support, etc..

In order to carry out contract development projects, Mr. Parvej Ali founded a business called APS Infra Projects in 2019. Our organization has bought several equipment for smooth operations. Strong team, a commitment to sustaining the highest quality standards attainable in the construction sector, and integrity have been the fundamental drivers of success. Ours was initially a partnership manufacturer and supplier firm which was later changed into a private limited company to sustain the expansion. Eventually, Mr. Bilal Khan and Ms. Farhana Khan became directors. Currently, our company is engaged in offering Stainless Steel Bridge Expansion Joint, Over Bridge Bearing Pad, Water Drainage Spout, Elastomeric Rubber Bridge Bearing, etc.

Company Facts

Quality, integrity, and honesty set us apart from other commercial road building firms. We are conscious of the importance of every single Road/Highways project, from small tenement restorations to massive multi-Crores projects. Every customer gets the specialized attention they require for their particular project.

Hot Products

Every customer gets the specialized attention they require for their particular project.

A Strip Seal Expansion Joint is a widely used bridge expansion joint system designed to accommodate movements due to thermal expansion, contraction, and other factors while maintaining a watertight seal and providing a smooth riding surface.

Below is a standard technical specification for Strip Seal Expansion Joints, suitable for bridge or highway works (can be adapted to project or regional standards such as ASTM, IRC, AASHTO, BS, or EN).

1. Scope

This specification covers the design, supply, fabrication, and installation of Strip Seal Expansion Joints for bridges and structures. The system shall accommodate movements up to the specified range while ensuring water tightness, durability, and skid resistance.

Send Inquiry

Send Inquiry Send SMS

Send SMS